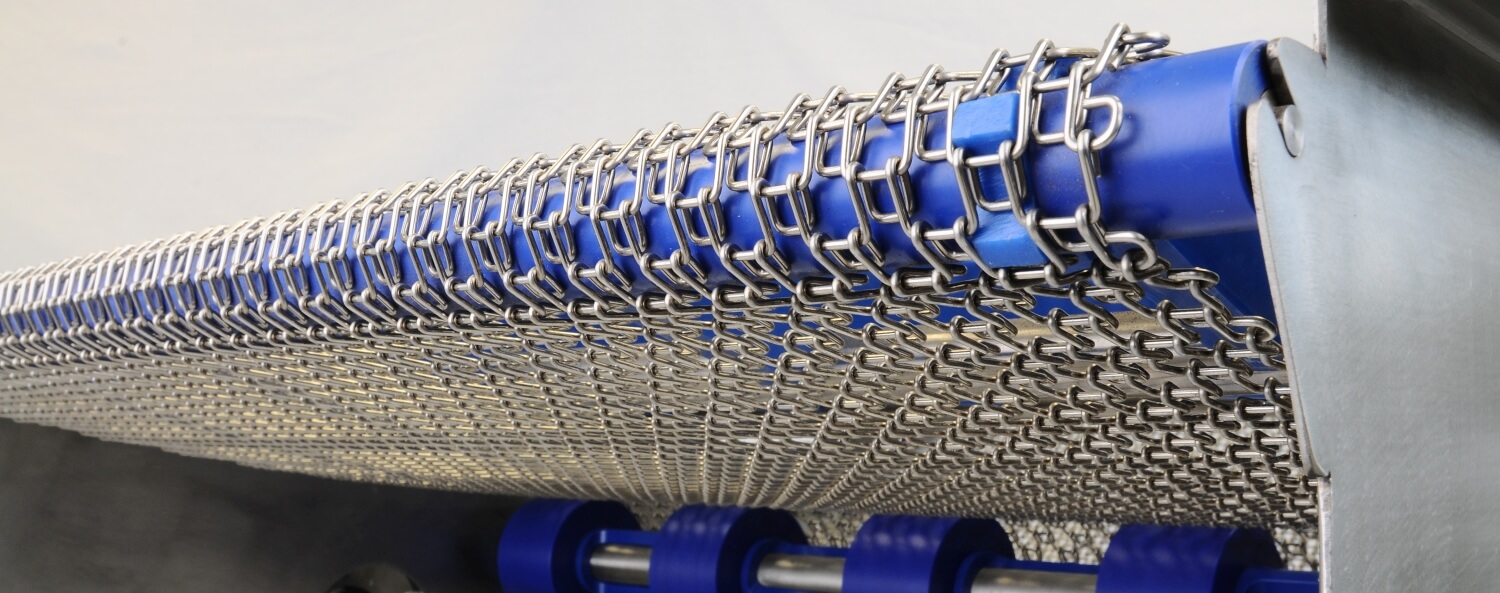

The Flat-Flex conveyor belt designs give you some of the tightest transfer options...with some meshes rotating around pencil-diameter transfer rollers. Different designs of transfer rollers and knife edges are used to facilitate transfer between different belts.

Transfer roles may or may not rotate. Rotating transfer rollers are usually preferred because they wear out less.

They are also usually edge supported and rotate at the same speed as the belt to minimize wear on the belt and pulleys. Different types of transfer roles are z. B. blanks, blanks and gears, grooved transfer rollers and freely rotating plastic transfer rollers.

However, the arrangement of the blanks and gears differs from that of the transfer rollers. Blanks and gears are set in pairs in the odd-numbered meshes, similar to the layout of the drive shaft. These are allowed in the Z-bends with an allowable spacing of 3-5mm. Conveyor rollers are placed with the groove under the Z-bend so that the Z-bends go around and over the rollers.

Conveyor rollers are preferred to non-rotating splined shafts or splined knife edges. The following sizes fit all types of handovers:

| Minimum Grooved Roll Dimension (mm) | |||

|---|---|---|---|

| wire pitch & diameter | Min. diameter of transfer roller (A) | Groove depth including space (B) | Min. diameter for negative deflection |

| 4,24 x 0,90 | 12 | 3,0 | 43 |

| 4,30 x 1,27 | 12 | 3,0 | 43 |

| 5,64 x 0,90 | 12 | 3,5 | 57 |

| 6,0 x 1,27 | 16 | 4,0 | 60 |

| 6,35 x 1,27 | 16 | 4,0 | 64 |

| 6,40 x 1,40 | 20 | 4,0 | 64 |

| 7,26 x 1,27 | 16 | 4,0 | 73 |

| 7,26 x 1,60 | 19 | 4,0 | 73 |

| 9,60 x 2,08 | 25 | 5,0 | 96 |

| 12,0 x 1,83 | 29 | 6,5 | 120 |

| 12,7 x 1,83 | 29 | 6,5 | 127 |

| 12,7 x 2,35 | 38 | 6,5 | 127 |

| 20,32 x 2,35 | 38 | 6,5 | 203 |