Spiral link belts made of flat and round wire, as well as transport belt braids with flat or round spirals, are widely used in various branches of industry. The areas of application are correspondingly varied. The drive can be frictional or form-fitting with toothed discs.

Wire link and wide spiral belts, transport belt braids - spiral belts cover a wide repertoire of belts for various applications. Often driven by friction, they offer a conveyor belt principle that is very easy to install. However, there is also the possibility of driving spiral belts by means of toothed wheels.

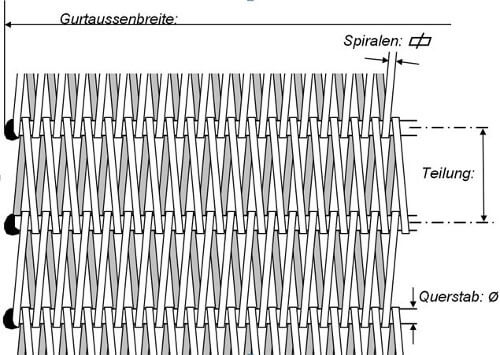

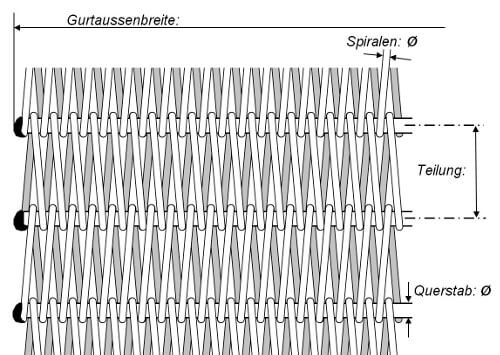

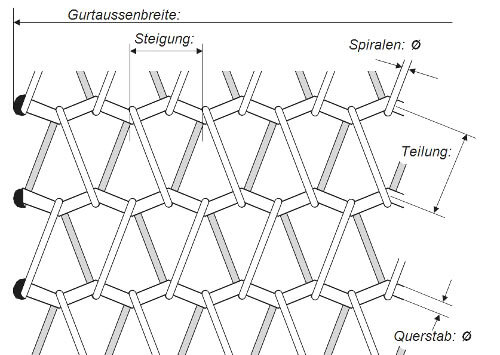

These belts consist of alternately arranged fine-meshed spirals that are connected to one another by transverse wires. The alternating construction and the crossbars give the belt stability and ensure that the belt runs straight. This type of belt is often used in ovens, washing, sterilizing and cooling systems, as well as in dewatering systems. Various branches of industry are served, such as the food industry (bakeries, vegetable and fruit processing, sugar, confectionery and chocolate industry), chemical industry, rubber and plastics industry, foundries.

The belts can be equipped with channel edges and/or drivers. In addition, hollow pin chains can be mounted to drive the belt via a chain guide.

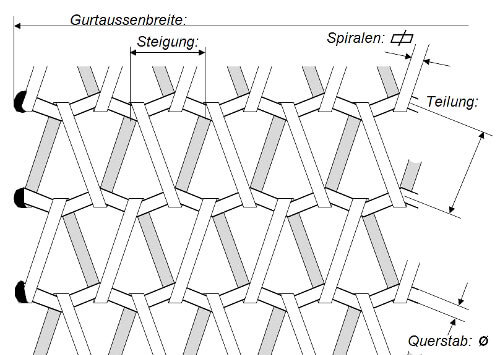

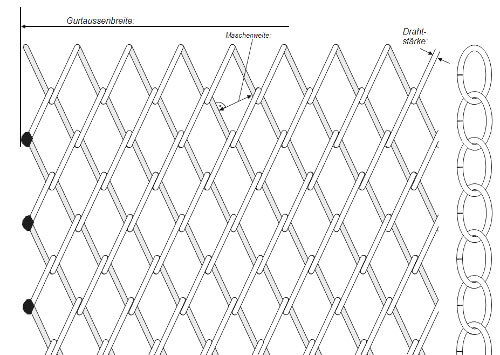

These belts have a similar structure to flat and round wire link belts, but have wide-meshed spirals and corrugated crossbars. The spirals are also arranged alternately. In addition to the food industry (vegetable processing, canning industry, bakeries), typical areas of application are also the glass industry, hard coal mines, foundries, the ceramics industry, leather goods processing, textile industry, drying houses, veneer and sorting companies.

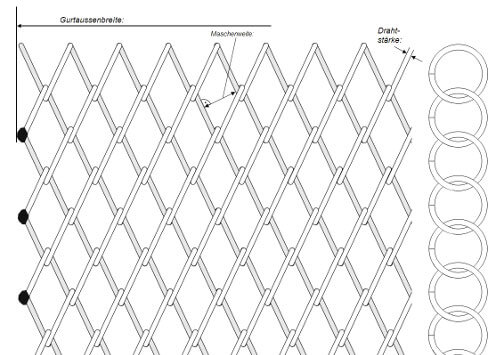

These straps represent the simplest type of spiral braids. They can be braided on one side or alternately. However, these are only suitable for transporting light products. They are often used as drying or cooling belts in biscuit, confectionery and ready-to-bake processing. Contrary to the typical use as a conveyor belt, transport belt meshes are also often used as protective grids or fence grids, e.g. for lifting platforms.

Edge finishing can be done as follows.

Bending edge (B-edge):

loop edge

Welded edge

hollow pin chain

|

belt outer width | to 5.000 mm |

| Division | 8,0 mm to 50,8 mm | |

| Spirals | 1,2 x 0,7mm to 4,0 x 2,0mm | |

| crossbars ø | 1,4 to 8,0mm; smooth or profiled | |

| bending | Looped, bent or welded edges |

|

belt outer width | to 5.000 mm |

| Division | 8,0 mm to 50,8 mm | |

| spirals ø | 0,8 to 5,0 mm | |

| crossbars ø | 1,4 to 8,0mm; smooth or profiled | |

| bending | Looped, bent or welded edges |

|

belt outer width | to 6.000 mm |

| Division | 4,0 mm to 50,8 mm | |

| Slope | 3,0 to 33,3 mm | |

| Spirals | 1,2 x 0,7mm to 4,0 x 2,0mm | |

| crossbars ø | 1,0 to 8,0mm; wavy | |

| bending | Looped, bent or welded edges |

|

belt outer width | to 6.000 mm |

| Division | 4,0 mm to 50,8 mm | |

| Slope | 3,0 to 33,3 mm | |

| spirals ø | 0,8 to 5,0 mm | |

| crossbars ø | 1,0 to 8,0mm; wavy | |

| bending | Looped, bent or welded edges |

|

belt outer width | to 6.000 mm |

| Spirals | 0,5 to 3,0 mm (oval shape) | |

| mesh sizes | 3,0 to 25,0 mm | |

| bending | Bended or welded edges |

|

belt outer width | to 6.000 mm |

| spirals ø | 0,5 to 2,0 mm (round shape) | |

| mesh sizes | 1,75 to 10,0 mm | |

| bending | Bended or welded edges |