Efficiency with curve conveyors at the push of a button. We call it Simply and Smart. Do you want the highest production quality? The reliable Flex-Turn® Curved conveyors guarantee proper transport of your products at every stage of the production chain, without changing their orientation. They offer the smallest possible product interface in their class. Gentle, always even transport minimizes the risk of damage to sensitive products. The compact design offers problem solutions for production systems in tight spaces. Tailored to your needs, your processes become simpler and more productive.

The Flex Turn® Series offers a selection of different sizes, belt widths and configurations for almost every application. Curve radii of 90° or 180° are our standard, but intermediate radii of 45° to 180° are also readily available.

There is Flex-Turn with a total of thirteen different band sizes, right and left orientation and radii between 45° and 180° to choose from® Curved conveyors for almost every application. Our standard drives and controllers have IP66 housing protection and OS2 surface protection (drive only) making them suitable for intensive washdown processes. On request, we configure customer-specific systems for individual requirements.

A variable frequency drive (VFA) can be fitted for the drive, allowing start/stop functions and speed controls. Normally, the VFA is installed in our standard control panel with a housing made entirely of stainless steel and including an emergency stop switch. Alternatively, an Invertek E3 Optidrive controller with a plastic housing and no emergency stop switch is available.

By default, Flex-Turn® Curved conveyor supplied with height adjustable support feet with mounting holes. As an option, they can also be supplied with lockable castors including brakes.

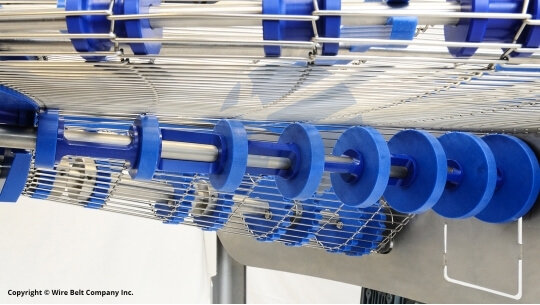

The system frame construction is made of stainless steel.

The contact surface is made of food grade blue polyethylene.

Three inside radii are available, each with a choice of different belt widths:

| Model 616, 716 & 816 specifications | ||

|---|---|---|

| Belt width | inner radius | available angles |

| 254mm | 406mm | 45° – 180° * |

| 406mm | 406mm | 45° – 180° * |

| 610mm | 406mm | 45° – 180° * |

| 864mm | 406mm | 45° – 180° * |

| 1092mm | 406mm | 45th - 90th |

| 1270mm | 406mm | 45th - 90th |

| Model 632, 732 & 832 specifications | ||

|---|---|---|

| Belt width | inner radius | available angles |

| 381 mm | 812 mm | 45° – 180° * |

| 622 mm | 812 mm | 45° – 180° * |

| 864 mm | 812 mm | 45° – 180° * |

| Model 680, 780 & 880 specifications | ||

|---|---|---|

| Belt width | inner radius | available angles |

| 400 mm | 800 mm | 45° – 180° * |

| 600 mm | 800 mm | 45° – 180° * |

| 900 mm | 800 mm | 45th - 90th |

| 1000 mm | 800 mm | 45th - 90th |

* Please contact our technical sales department for any application with an angle greater than 90°